・As the casing is fully open and the basket is in front of the operator, it is easy to clean and check the inside of the basket as well as the back of the basket.

・Since slurry supply, separation, cake washing, crystal recovery, and cleaning can be processed fully automatically without human intervention, contamination due to operator intervention does not occur.

・By using a metal filter material, it is possible to prevent the contamination associated with a filter cloth.

・The holes in the metal filter material (electronic beam) have a special shape, so there is no washing residue left in the holes of the filter material.

・Cleaning can be reliably performed even in narrow gaps between the inner side of the basket bottom and boss (cylindrical part), and between the upper part of the casing bottom and the outer surface of the bearing case, which was not previously possible, and flushing, wiping, and cleanliness can be checked.

・The device is ideal as a GMP- and FDA-compatible centrifuge because it can perform sufficiently clean centrifugal separation even when the treated material is changed.

・Various recipes can be programmed, and various safety devices are provided, so automated operation is possible.

・The basket lift-up device raises the basket itself. This makes it easy to visually check the back of the basket, shortening the cleaning time and saving on labor.

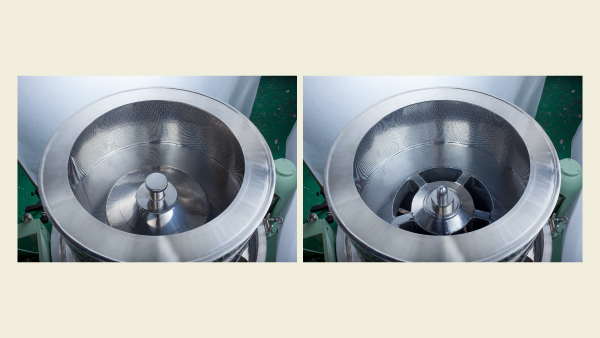

・By adopting a multi-blade structure for the residual crystal scraper device (Matsumoto Machine patent), it is possible to recover crystals with the highest efficiency up to the limit of the filter cloth. A nozzle is attached to the scraper device, and by injecting high-pressure air or nitrogen gas, the remaining crystals of the filter cloth can be detached and recovered with the highest efficiency. The device also facilitates the removal of liquid during reuse.

・When processing different chemicals, the filter cloth can be washed using high-pressure water, increasing efficiency.

・Using a metal filter eliminates the need to replace a filter cloth.

・All Matsumoto Machine centrifuges are custom-made. Regardless of the model, we respond to all requests, so please feel free to contact us if you have any requests or questions. After confirming the desired usage and conditions, our technicians will design from scratch and make a custom-made device.